A philosophy with quality

OUR CUSTOMERS DESERVE QUALITY.

Our products and services will meet all of your needs, especially in terms of quality, and economic efficiency and including environmental and occupational safety. We identify with your needs by meeting your targets timely and efficiently with expert skills and at competitive conditions.

A FUTURE OF QUALITY.

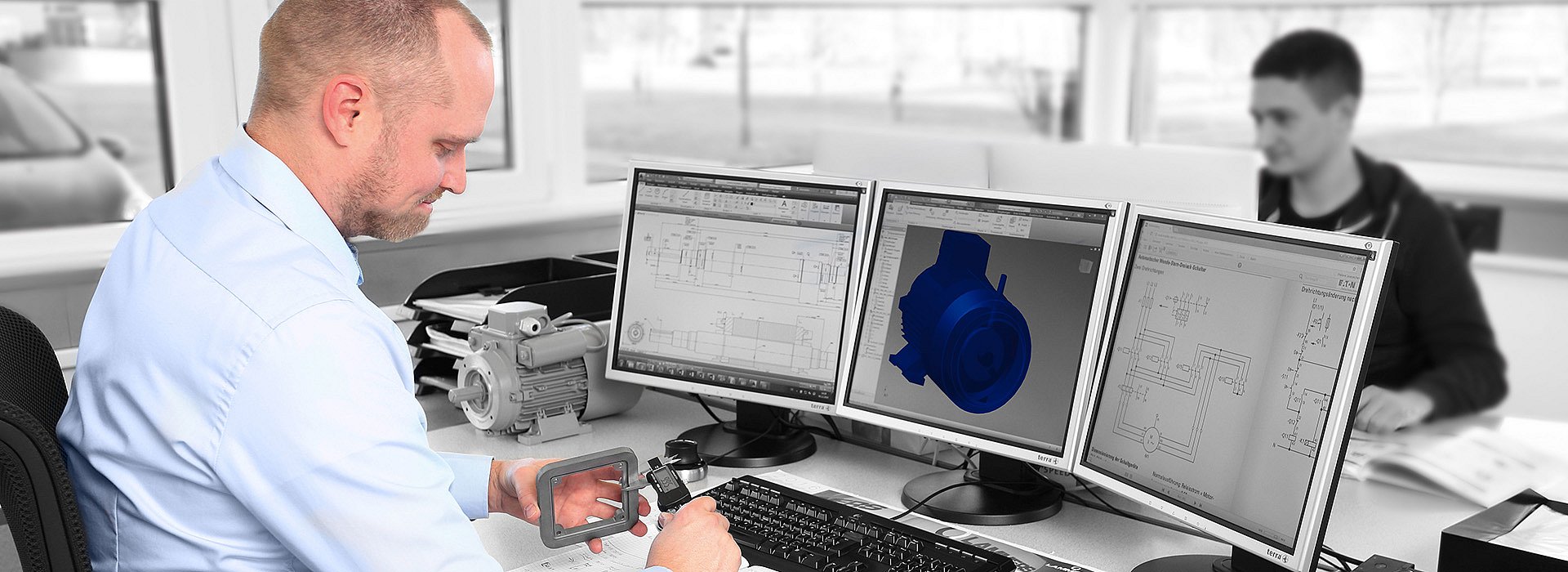

Our employees carry out every step in mechanical and electrical processes at our headquarters to keep up

with the high standards of quality we set ourselves.

You can rely on timely delivery,

even if we’re talking about special designs or modifications.

Quality is our motivation for pursuing this principle

today, tomorrow and in future.

Locations

Lammers Quality.

HISTORY

Quality with history.

Whoever wants to be a symbol of the highest quality for decades has to keep moving – this has been our conviction since 1946.

That is why we have expanded and consolidated our competencies from the start and

we have continuously expanded our storage and workshop space.

Take a look at our history:

Certifications/ AcceptanceQuality with distinction.

general CLASSIFICATION

- ISO 9001 – ISO 45001 – ISO 14001

- Nachhaltigkeitsvisitenkarte

- Siemens Service-Delivery-Partner

- ATEX Zone 2

- ATEX Zone 21

- ATEX Zone 22

MARINE-CLASSIFICATION:

- Bureau Veritas

- Rina 1861

- DNV GL

- Lloyd's Register

Sustainability Business card

Sustainability services by Clemens Lammers GmbH & Co. KG

Die Clemens Lammers GmbH & Co. KG presents its path towards sustainability as part of this sustainability business card.

According to the dimensions of sustainability, economy, environment and social issues are given equal priority and at the same time are thought and implemented. This happens very concretely in everyday company life. The building, the sustainable personnel policy and the economic stability are proof of the sustainability performance.

The sustainability business card is implemented with the Institute for Sustainability Education in Münster. It is based on the criteria of the German Sustainability Code (DNK) based on a so-called DNK classification.

DNK-classification

German Sustainability Code (DNK)

The Federal Government's Council for Sustainable Developmenthas developed the so-called German Sustainability Code (DNK). The DNK offers companies the opportunity to make sustainability performance visible and comparable based on 20 criteria.

The Institute for Sustainability Education offers companies a DNK orientation based on the DNK criteria.

DNK classification for Clemens Lammers GmbH and Co. KG

Q-four principle

The Q-four principle of Clemens Lammers GmbH & Co. KG

The quality of products and services is an essential prerequisite for sustainable development. Aspects such as longevity, reliability and repairability save resources.

Clemens Lammers GmbH & Co. KG bases this principle on the so-called Q-four principle. In the field of electrical drive technology, a qualitative complete package is offered: drive technology, special drives, service & maintenance and diagnostics.

Quality has been the trigger and goal for every decision since 1946: all work steps, processes and services bear the "Q" for quality like an embossed symbol. That is why the company takes responsibility - for the production systems, the products and the drives of the customers.

economics

Sustainable growth in the region

As a medium-sized company in the district of Steinfurt, "sustainable" growth is generated. Solid business management, long-term personnel and investment decisions, added value in the region in a future-oriented industry characterize the company's development with meanwhile over 100 employees at the Rheine location.

Quality orientation is the formula for success. As the largest specialist company for drive technology and market leader in the region, all mechanical and electrical processing steps are implemented in-house. The principle is full level through consistent interlocking.

In times of a shortage of skilled workers, the company relies on the next generation. A high training quota impressively documents this.

ecology

Pioneers of sustainable building

In 2007, standards in sustainable construction were set at today's company headquarters. The commitment at the time met with a positive response in the region. A high-quality insulation, an ecological lighting concept and the district heating supply based on biogas are particularly noteworthy. District heating is supplied by neighboring farmers. This also underpins the company's claim to be a regionally responsible company. Furthermore, 100 percent green electricity is purchased.

The transparent construction creates an open and positive atmosphere. It is literally a transparent company - for employees, customers and neighbors. The design also affects electricity consumption.

Social

Employees as a guarantee of economic success

The employees are the most important part of the company. That is why health and safety are the basis for successful business. The constant training of employees is also of great importance. Employees and colleagues live fair, open, helpful and targeted dealings with each other. There is an awareness that only the common pursuit of goals will be successful in the long term.

The employees are challenged and encouraged.

Employee awards and anniversary grants, joint activities and celebrations, opportunities to stay in the outdoor area and fresh fruit every day are elements of a sustainable personnel policy.

The low employee turnover is an expression and result of this commitment.

ESuccessful trainees

The future viability of a company requires perspective personnel planning. With a training quota of around 20 percent, the company contributes to our long-term economic stability and makes an important contribution to society. Since 2017, two asylum seekers have also started their training in the company. Trainee mentors accompany the young people on their professional path to the company and act as contacts during the training.

The trainees will a. recruited by participating in career orientation days. There are also opportunities to do internships.

The performance of the trainees develops in line with the quality orientation. In this way, trainees have already been awarded chamber winners.

sustainability officer

sustainability officer

With Lisa Ebbers-Fier, Clemens Lammers GmbH & Co. KG has a trained sustainability officer.